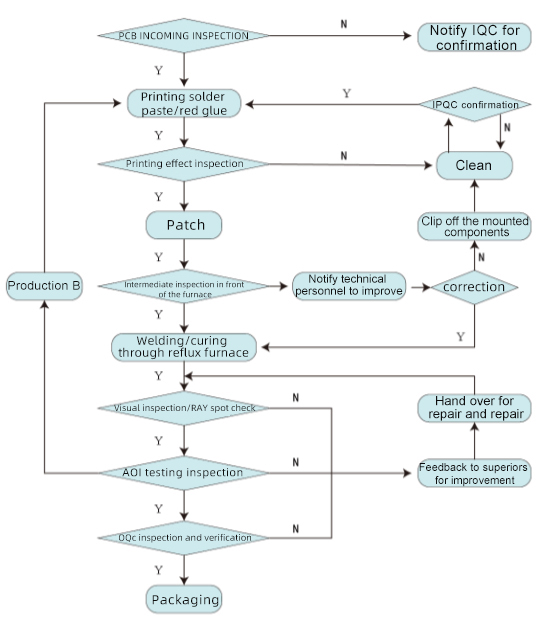

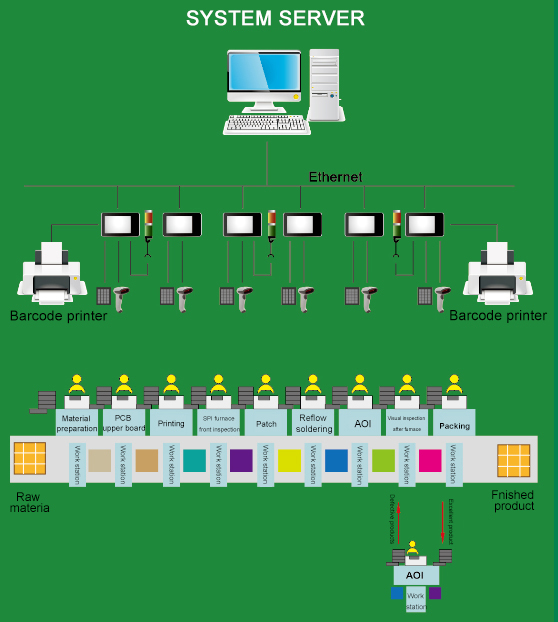

SMT production process

SMT chip mounting processing is a series of process technologies that are processed on the basis of PCBs, with advantages such as high mounting accuracy and fast speed. The SMT chip processing process mainly includes printing, chip mounting, solidification, reflow soldering, testing, repair, etc. Multiple processes are carried out in an orderly manner to complete the entire chip processing process.